Understanding Electromagnetic Interference (EMI)

What is EMI?

Electromagnetic interference, or EMI, is unwanted noise or signals that interfere with the normal operation of electronic circuits. It can be categorized into two types: radiated EMI, which travels through the air, and conducted EMI, which is transmitted through conductors.

Sources of EMI in PCBs

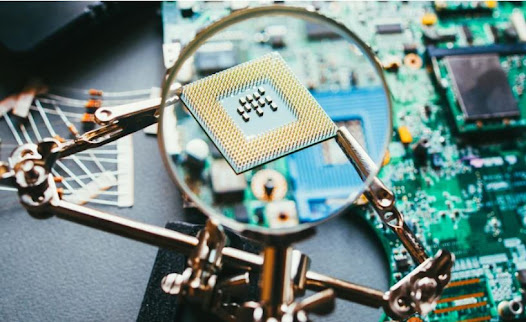

EMI in PCBs can originate from various internal and external sources. Internally, components like high-speed digital chips, switching power supplies, and oscillators can generate EMI. Externally, EMI can come from other electronic devices, radio transmissions, and even natural phenomena like lightning.

Effects of EMI on Electronics

The consequences of EMI on electronic devices can range from minor annoyances to critical failures. It can cause data corruption, signal degradation, unexpected device behavior, and in severe cases, damage to the components.

Strategies for Reducing EMI in PCBs

PCB Layout Design

- Component Placement: Careful placement of components can significantly reduce EMI. Keep sensitive components away from high-speed or high-power parts to minimize interference.

- Signal Routing: Use short, direct traces for high-speed signals and avoid parallel routing with other high-speed traces to reduce crosstalk.

- Layer Stacking: A well-thought-out layer PCB stack can shield sensitive traces and components from EMI. Utilize ground planes effectively to provide shielding and a return path for signals.

Grounding and Shielding

- Solid Ground Planes: Implement solid ground planes to reduce loop areas and provide an effective shield against EMI.

- Shielding Components: Metal shields can be used to encase noise-generating or noise-sensitive components, isolating them from the rest of the PCB.

Filtering and Decoupling

- Decoupling Capacitors: Place decoupling capacitors close to the power pins of integrated circuits to filter out high-frequency noise.

- EMI Filters: Use EMI filters on power and signal lines to block unwanted high-frequency noise while allowing the desired signals to pass through.

Differential Signaling

- Using differential pairs for transmitting signals can significantly reduce EMI. Differential signals cancel out noise that is picked up along the transmission path, enhancing signal integrity.

Avoiding Common Design Pitfalls

- Split Ground Planes: Avoid splitting ground planes, as this can create large loop areas and increase susceptibility to EMI.

- Trace Corners: Use 45-degree angles or curves for trace corners to minimize reflections and radiated EMI.

Testing and Certification

Pre-Compliance Testing

Conducting pre-compliance EMI testing during the design phase can identify potential issues early, saving time and costs associated with redesigns.

Certification

Understanding and complying with EMI regulations is crucial. Ensure your PCB design meets the necessary standards and certifications required in your region or industry.

Case Studies and Real-World Applications

Consumer Electronics In the highly competitive consumer electronics market, minimizing EMI is crucial for the reliability and user experience of devices like smartphones, laptops, and wearables.

Automotive Industry The automotive sector, with its increasing reliance on electronic systems, requires stringent EMI control to ensure safety and performance in harsh electromagnetic environments.

Aerospace and Defense In aerospace and defense, where systems operate in extremely high-EMI environments, robust EMI mitigation strategies are essential for mission-critical applications.

Conclusion

Reducing electromagnetic interference in PCBs is a complex but crucial aspect of electronic design. By understanding the sources and effects of EMI and implementing strategic design and testing practices, engineers can create more reliable, high-performance electronic devices. As technology advances, the challenge of EMI will continue to evolve, requiring ongoing learning and adaptation from professionals in the field. With a proactive and informed approach to EMI reduction, you can ensure your PCB designs meet the highest standards of quality and reliability in an increasingly electronic world.

FAQ Section

What are some common symptoms of EMI in electronic devices?

Can EMI cause permanent damage to electronic components?

How does the frequency of a signal affect its susceptibility to EMI?

Are there any specific materials used in PCBs to reduce EMI?

How do international EMI standards vary, and what should designers be aware of?

By addressing these questions and more, this guide aims to empower PCB designers and engineers with the knowledge and tools to tackle EMI challenges effectively, ensuring the optimal performance and reliability of their electronic products.