Complexity in Supply Chain Management: Managing a supply chain for HMLV manufacturing is notably complex due to the need for a diverse range of materials and components. PCB manufacturers must maintain relationships with numerous suppliers to ensure the availability of various components, which can vary significantly from one batch to another. This diversity increases the risk of supply chain disruptions.

Inventory Management: Efficient inventory management becomes a significant challenge in HMLV environments. The necessity to stock a wide variety of components, many of which may have long lead times or minimum order quantities, can lead to increased inventory costs and potential wastage if the components go unused.

Production Scheduling and Flexibility: Scheduling production runs efficiently in a HMLV setup is complex due to the frequent changes in production requirements. Manufacturers must have flexible production lines that can quickly switch between different PCB designs without significant downtime. This requires sophisticated planning and potentially automated systems for setup changes.

Quality Control: Ensuring consistent quality across a range of products is more challenging when each product is made in small quantities. The variation in production processes and materials can lead to quality inconsistencies, requiring robust quality control systems and frequent testing.

Cost Management: Cost control is particularly difficult in HMLV manufacturing. The economies of scale achieved in high-volume production are absent, making it harder to spread out the fixed costs. Additionally, the frequent switching between tasks and setups can lead to increased labor and overhead costs.

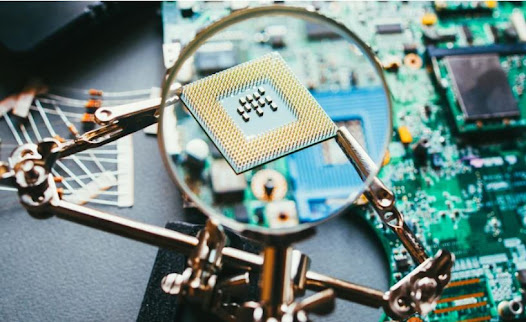

Technological Integration: Adopting and integrating advanced manufacturing technologies (like automation, IoT, and AI) that can handle diverse and rapidly changing production requirements is crucial. However, this involves significant investment in terms of both money and time.

Customer Relationship Management: HMLV manufacturing often requires closer interaction with customers to understand their specific needs and respond swiftly to changes. This demands more robust customer service and project management capabilities.

Design and Development: The design and development phase in HMLV manufacturing needs to be highly efficient to handle customizations. This requires skilled personnel and possibly more sophisticated software tools to design and prototype quickly.

Overcoming these challenges requires a strategic approach to process design, an investment in versatile machinery, skilled workforce training, and a robust IT infrastructure to manage the complexity inherent in HMLV PCB manufacturing. those EMS, ODM or OEM customer that looking for a great HMLV PCB manufacturing server can discover essential technologies that can support high-mix, low-volume PCB manufacturing service, including tools for automation, advanced scheduling, and flexible production systems, to address the unique challenges of this production model effectively.