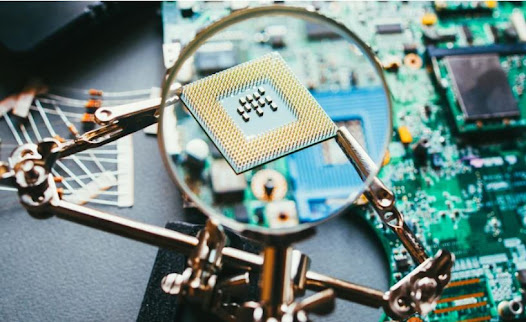

Integrated Circuit (IC) test boards are critical in ensuring the reliability and performance of electronic components in various applications, from consumer electronics to industrial systems. As technology progresses, the demands on PCB design and manufacturing evolve, requiring more sophisticated and advanced pcb solutions. This blog post for you to explore more of IC Test Boards, understanding their crucial roles and various types such as ATE, Probe Cards, Load board, SLT Board and BIB Boards.

ATE Test Boards

Automated Test Equipment (ATE) test boards are crucial for mass testing of ICs, ensuring that they meet the required specifications for performance and reliability. These boards are designed to interface with complex electronics to simulate real-world conditions, verifying the functionality of ICs under various scenarios.

Probe Cards

Probe cards are essential in the semiconductor manufacturing process, used to test the electrical performance of wafers before they are cut into individual chips. They must support large, high-multilayer PCB designs, accommodating the increasing complexity and miniaturization of semiconductor devices.

Load Boards

Load boards are used to mount the device under test (DUT) and connect it to the ATE for performance evaluation. These boards are used during the final testing phase of semiconductor manufacturing. They load the IC to simulate its real operating environment, ensuring the chip operates reliably under intended conditions.BIB Boards

BIB (Burn-In Boards) are crucial for reliability testing under stress conditions. These are utilized to perform reliability testing under forced conditions to accelerate the failure processes. Modern BIBs manage small pitch requirements, which is vital for testing newer, smaller form factor ICs.SLT Boards

System Level Testing (SLT) boards are used for final testing, simulating the actual operating environment of the ICs. They are characterized by their high density and the ability to test multiple ICs in conditions that mirror their final application.

Advanced PCB Design and Manufacturing

High Multilayer Design

Modern IC test boards often require a high number of layers to accommodate the increased functionality. Managing signal integrity and minimizing interference between layers are critical challenges that need advanced PCB design techniques and materials.

High Aspect Ratio Drilling

The drilling of high aspect ratio holes, which are deeper than they are wide, is a significant challenge in PCB manufacturing. These are necessary for creating vias in multilayer PCBs but require precise drilling technology to maintain integrity throughout the board.

Equipment Requirements

Manufacturing these sophisticated PCBs requires state-of-the-art equipment, including high-precision drilling machines, advanced imaging techniques, and automated inspection systems to ensure that every layer aligns perfectly and functions as intended.

Finding a Reliable PCB Supplier

Selecting the right PCB supplier is critical. Key criteria should include advanced manufacturing capabilities, a proven track record of reliability, and robust quality assurance practices. Suppliers must also be able to adapt quickly to the evolving technologies and demands of the PCB industry.

Latest Trends and Future Outlook

The IC test board industry is experiencing rapid advancements, such as the integration of machine learning algorithms for predicting and diagnosing faults more efficiently. Looking ahead, further miniaturization and integration of electronic components will likely drive innovations in PCB design and testing methodologies.

Cost-effective Solutions for Startups

Startups can obtain cost-effective solutions by partnering with suppliers that offer scalable production options and negotiating flexible terms that accommodate growth. Bulk purchasing and leveraging industry networks for recommendations on suppliers can also lead to significant cost savings.

Conclusion

IC test boards are integral to the electronic manufacturing process, ensuring that every component performs to its highest standard. As the complexity of electronic devices increases, the need for advanced PCB solutions grows. Choosing a reliable PCB supplier who can navigate these challenges is crucial for maintaining a competitive edge in the industry.

This comprehensive guide covers all critical aspects of IC test boards and offers valuable insights into both current practices and future trends, ensuring it is both informative and accessible for professionals in the field.